We Are A Tiny Controls Company That Has Solved Some Costly Problems Within The Pulp And Paper Industry.

About Pneu-Logic Co.

The impossible may take a little longer.

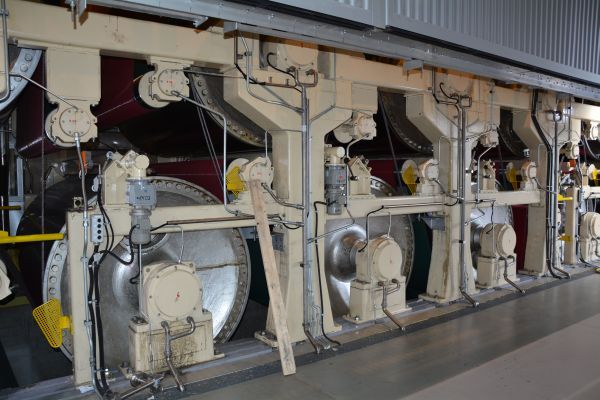

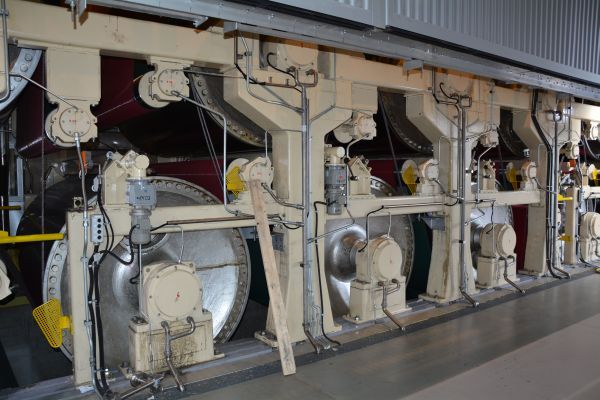

DCS Based Early Felt / Fabric Run-Off Alarming System

Scanner Based Stock Delivery System Optimization

Hydrapulper Based Consistency Control